Healthcare workers are telling mask manufactures all they need to know...

These faces speak volumes to the underlying disposable mask design problems worth solving for the sake of millions of healthcare workers. If you are a manufacturer and have recently joined the effort to produce and distribute surgical and or respirator type N95 mask products by replicating proven and established mask designs, then you are well contributing to the immediate need to reduce mask supply shortages. This path along with the FDA's current EUA program provides your organization a rapid process to bring useable product to market and help close the gap between supply and demand. This path likely does not include addressing outstanding user needs or mask product performance improvements beyond the current disposable mask offerings.

To sustain your manufacturing business for the long run well after this pandemic rush has settled you are likely considering how and when to invest the resources and time necessary to distinguish yourself with a superior "purposefully" designed mask product. At that time the competition will be fierce and a number of businesses who have made recent capitol investments to supply product for the current demand may not transition well when mask supplies meet the market demand. Performance improvements you identify, plan, and instill now will provide you a competitive advantage over the competition and ensure that your product stands out from one in a million other standard disposable mask products.

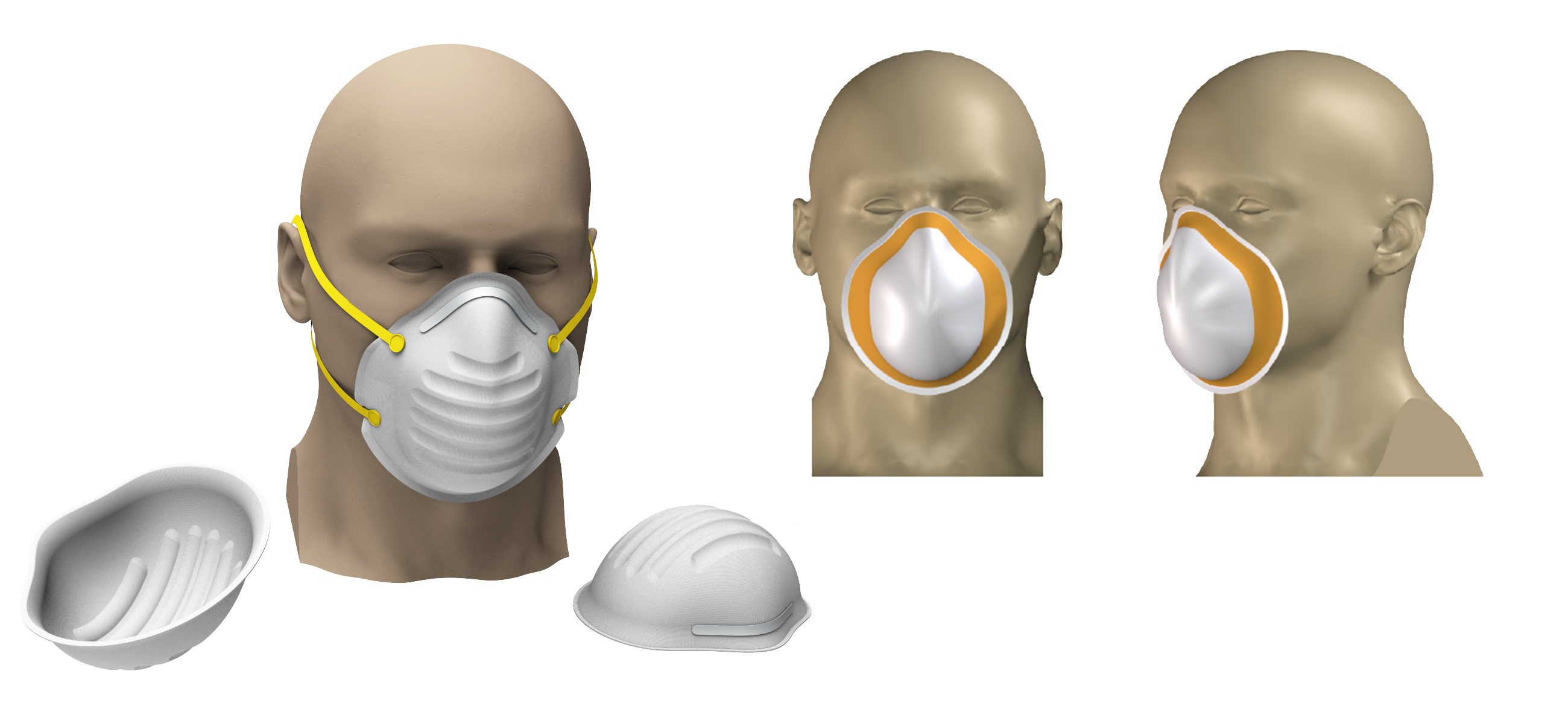

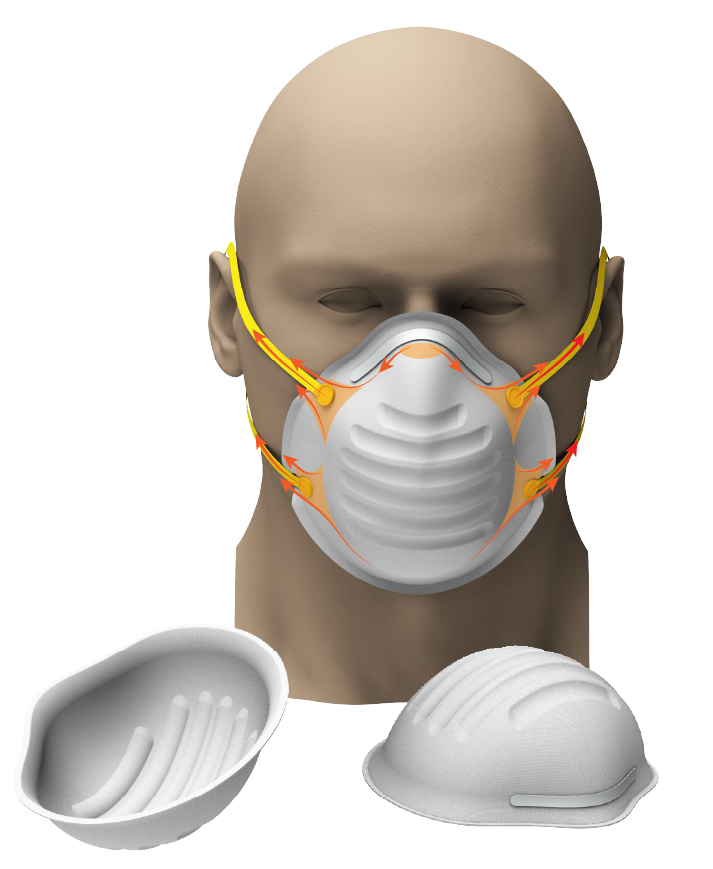

At ID8 Design we are busy evaluating mask user feedback being shared by an estimated 18 million healthcare workers domestically. We are compiling the knowledge that defines foundational problems not addressed with current disposable mask product offerings. A common problem workers experience is the development of skin ulcerations from heavy mask usage. They are highly susceptible to ulcerations due to prolonged skin contact, trapped moisture (sweat), poor mask fit and an uneven distribution of force exerted by fixation or tension straps used to achieve a proper perimeter seal to the face. Also disposable mask designs often lack adequate features to support free movement of the jaw during conversation. The images shared below illustrate the point load and lateral forces translated to hard points across the nose, cheek, and jaw bone locations. These locations have less muscle and fat layers over the cartilage and bone to distribute forces through tissue mass.

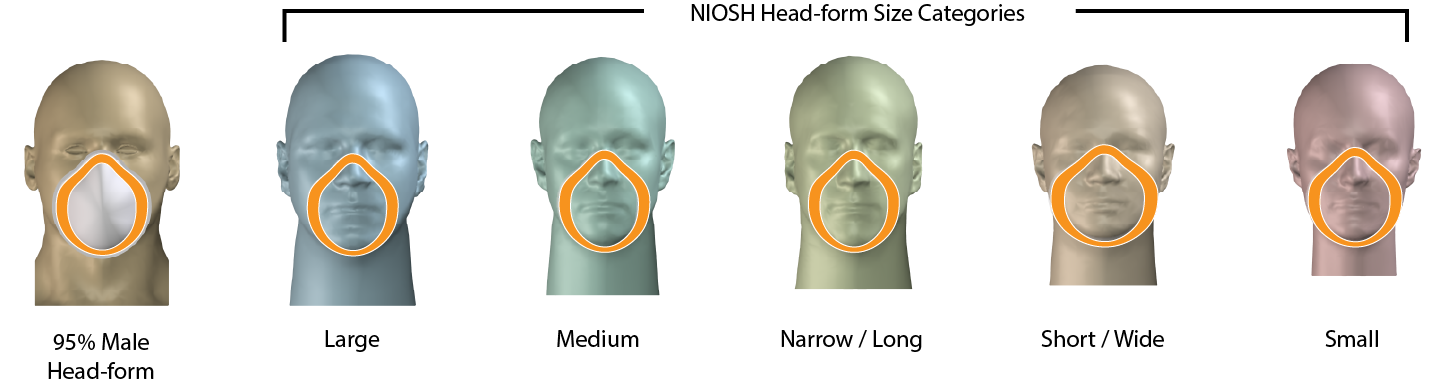

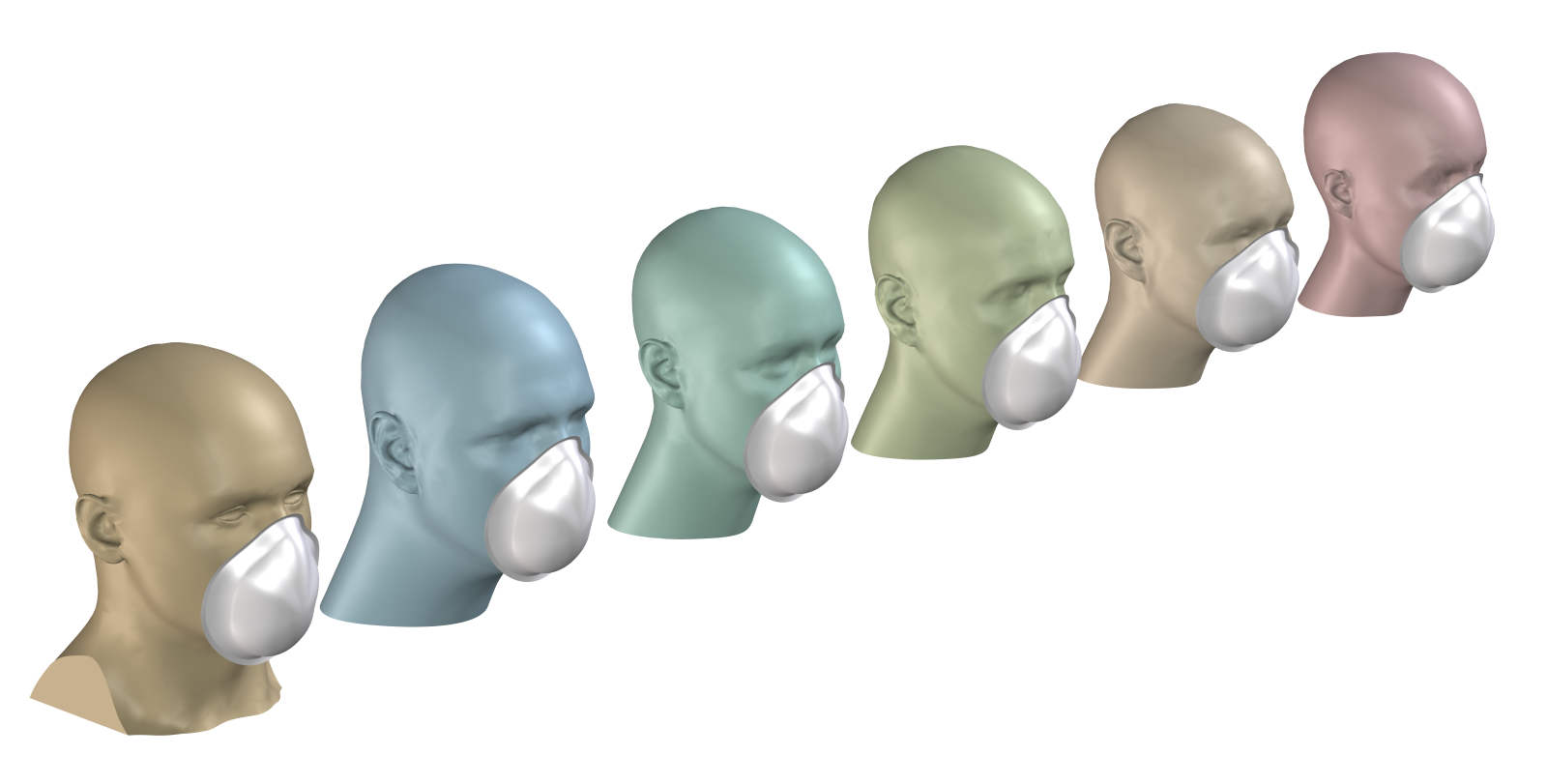

We are leveraging common industry technologies and tools provided by leading manufacturers and governing regulatory bodies like NIOSH (sizing head-forms shown below), to better understand to underlying issues we have identified during the evaluation process. These inputs are the foundation necessary to support innovative problem solving and detailed development. A mask's user contact surfaces require excellent compliance to create and maintain a face perimeter seal to a wide variety of head-form shapes and sizes. This area also requires proper support to maintain this seal throughout constant facial movements. The image below illustrates the compliant contact surface area (colored orange), of a single cup style mask product applied to multiple NIOSH regulatory head-forms.

Mask design innovation and development is best served by a multi-disciplined development team sharing knowledge concurrently to identify and solve outstanding user needs, material applications, and production processing. Your mask design efforts will instill best practices for medical device development addressing all regulatory requirements of both the FDA and CDC which will be in full force when the current EUA's are lifted. This is not a trivial effort as you need to ensure your new product will meet these requirements and achieve the high performance of a "gold standard" mask product ready for distribution.

This is an opportunity to invest and work for the greater good. We look forward to sharing more about potential solutions over the next couple of months. Stay tuned... ID8.design